Toxic Gas Monitoring Systems for Oil and Gas Drilling Rigs

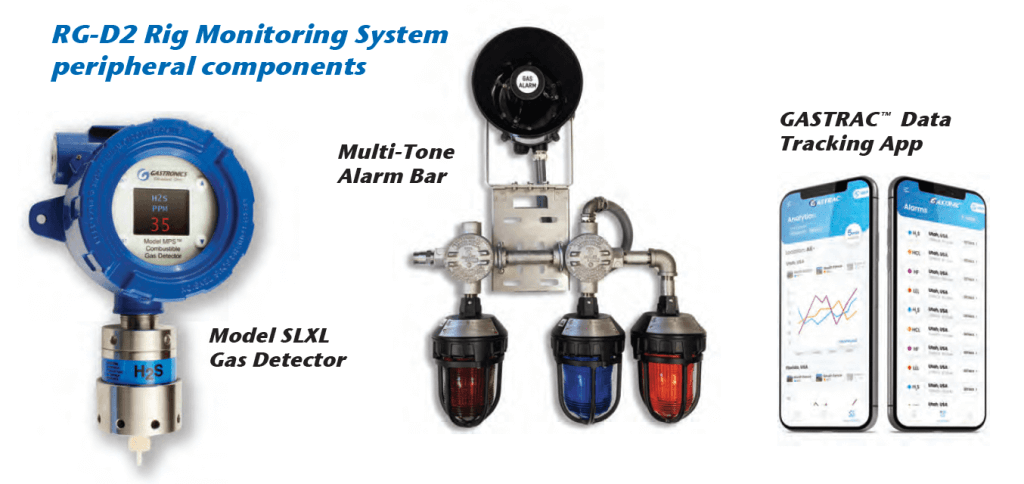

The Gastronics RG-D2 Rig Monitoring System is the ultimate solution in gas monitoring and controls for Oil and Gas Drilling. The controller is designed to detect and alert users to any potential gas leaks, ensuring the safety of workers and equipment. The RG-D2 Controller is built to withstand harsh industrial environments and is made with high-quality materials for long-lasting durability.

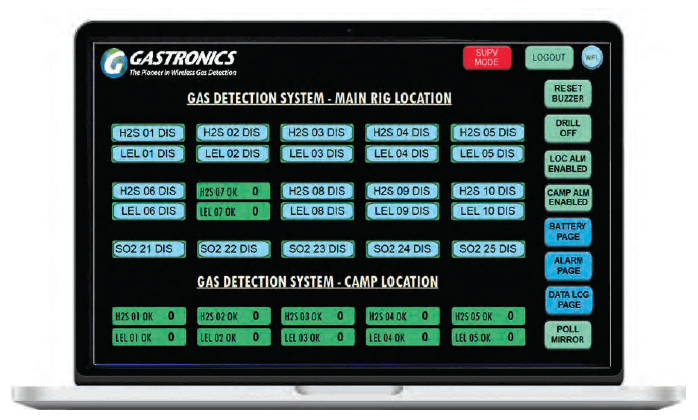

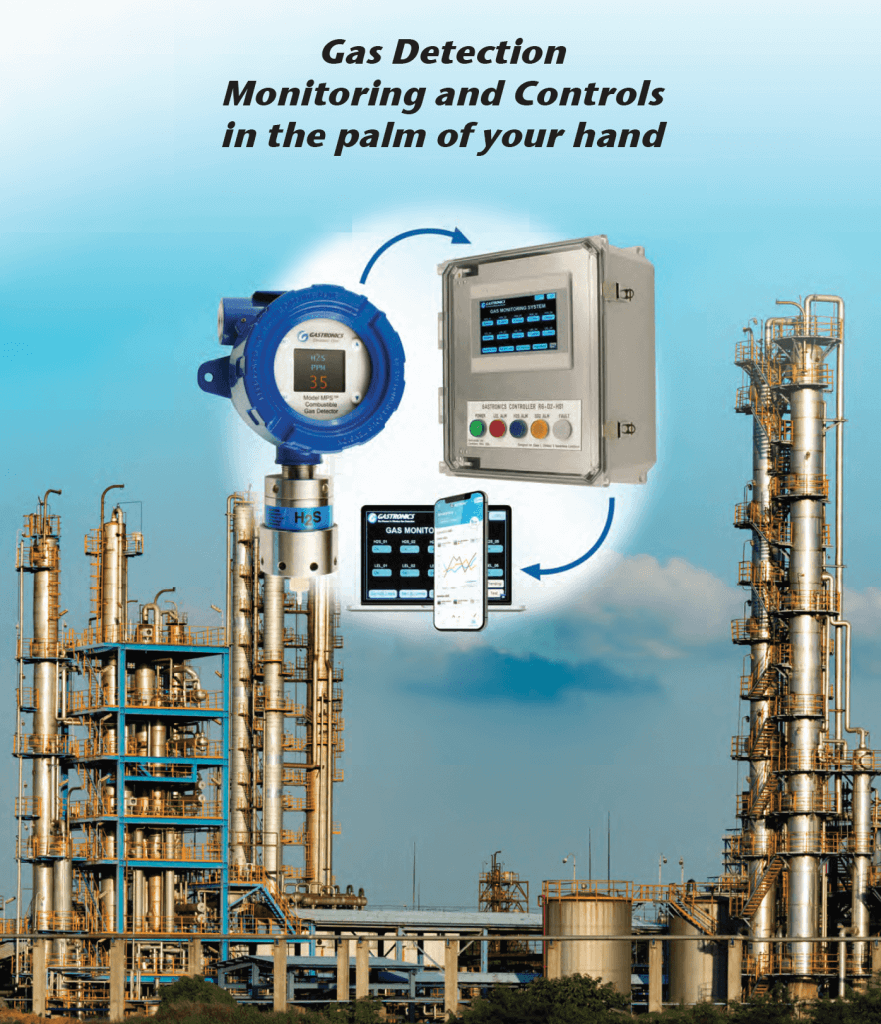

At the helm of the RG-D2 Rig Monitoring System is the RG-D2 Controller, which is equipped with an easy-to-use HMI interface. The HMI interface is available with a 7” (C1D2) or 10.1” (Non-Haz) interactive viewing screen, allowing users to monitor real-time gas readings and alarms, and perform various needed functions. The controller has multiple useful ports that allows it to be connected to one or more mirror controllers as well as provide remote programing maintenance using EasyAccess 2.0 software. But staying in control of your system does not end there. The RG-D2 controller can communicate in real-time with the GASTRAC™ Smart Phone Data App, which allows a hierarchy of users to receive in real-time, alarms, gas readings, diagnostics, and historical data, all in the palm of your hand.

Expandable Channel Cards and Custom Program designs allow for each system to be tailored to individual needs. The controller components are available for both Class I, Division 2 Hazardous Locations as well as non-Hazardous Locations. The Class I, Div. 2 Controllers are expandable to 32 wired channels. The Non-Hazardous controller versions are expandable up to 64 hardwired channels and 64 wireless channels. Control capabilities include an HMI touch screen that offers Drill Alarms, Alarm Test, Alarm Set, Reset, Channel Disables and user ability to label each channel location. HMI security features a login function to protect from tampering with functions. An HMI buzzer along with large, easy to see, LED indicators provide notification for Power, Gas Alarms, and Fault. Alarm Relays are available in single, dual and four pole configurations accommodating multiple output functions as needed. An RS485 Modbus-RTU output is standard for tying into a remote device, such as a Mirror Controller.

Interactive User Interface – More Channels for More Locations

The controller HMI screens are custom configured to suite the users needs. Multiple, selectable display screens can be configured to include additional channels, event logs, trend charts, diagnostic functions and more. Gastronics Gold Star customer support is ready to provide ongoing support to make future changes for various configurations.

HMI Viewer*

Our HMI Viewer is a network client application that enables users to view and control HMI devices and screens, quickly and easily from remote locations. This enables multiple client devices to connect to a single

HMI server with each client device providing an interactive and responsive user experience.

Easy Access 2.0

With Easy Access 2.0, you can easily monitor and troubleshoot the HMI from a remote location as long as an Internet connection exists. Easy Access 2.0 manages all network settings and security issues so the user simply connects to the HMI as if they were on the local network. Instantaneously view screens or implement updates to an HMI project.

RG-D2-MIR Mirror Controller

The RG-D2 controller can be coupled with the RG-D2-MIR mirror controller designed to accommodate the needs of drilling rigs suitable for Class I, Division 2. The RG-D2 is intended to be located in the rig “Dog House” for control and supervision by the operator, with the mirror located in a non-hazardous area such as the rig managers office.

The mirror controller is also available in Class 1, Division 2. The Main Controller and Mirror Controller are connected together via RS485. Features included on the Controller HMI’s allow the users to activate Drill Alarms, Test Individual Relays, Disable Sensors, View Historical Trends and Store Data on an SD Card.

Factory Acceptance Testing

Gastronics provides superior quality control with stringent Factory Acceptance Testing. Each system is functionally and performance tested prior to shipment. (F.A.T. documentation is provided with every system shipment.)